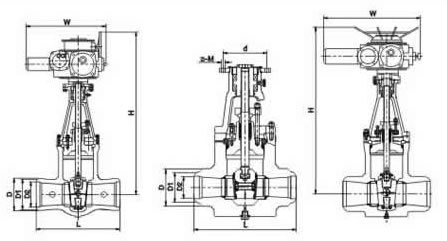

Z961Y-P54100V,Z961Y-P54140V,Z961Y-P54170V high temperature and high pressure electric power station gate valves:electric,butt welded connection form,rising stem wedge rigid single gate valve,valve seat sealing surface material is chromium molybdenum vanadium steel welded cobalt chromium tungsten alloy,working pressure is 10MPa~17MPa,valve body material is chromium molybdenum vanadium steel high temperature and high pressure power station gate valve.

1.Designed and manufactured according to standards such as JB/T3595,it can be used in conjunction with domestic equipment

2.The valve chamber adopts a pressure self tightening sealing structure with good sealing performance,and the two ends of the branch pipe are welded structures.

3.The sealing surface of the gate and valve seat is made of Stellite cobalt based hard alloy welded,which has good wear resistance,high temperature resistance,corrosion resistance,and abrasion resistance.

4.The valve stem has undergone quenching and surface nitriding treatment,providing excellent corrosion resistance and abrasion resistance.

5.The structure of the opening and closing components can be designed in different forms such as single board,double board,parallel double board,etc.according to user requirements.

Reference standard for gate valves of high temperature and high pressure electric power stations

The manufacturing and acceptance technical conditions shall comply with the provisions of Japanese standard E101 and JB/T3595-93 for valves used in thermal power generation;

The structural length shall be in accordance with E101 or the size provided by the user;

According to the management standard 78DG for welding bevel joints in the power industry,or based on the size provided by the user.

Main technical parameters of gate valves for high temperature and high pressure electric power stations

Model | Test pressure(MPa) | Working pressure(MPa) | operation temperature(℃) | Applicable Medium | ||

strength test | Sealing Test/Upper Sealing Test | |||||

Z960Y-250 | 25 | 37.5 | 27.5 | - | ≤425 | Water, steam |

Z960Y-320 | 32 | 48.0 | 36.0 | - | ≤425 | |

Z960Y-P54100 | - | 30.0 | 22.0 | P5410 | ≤540 | steam |

Z960Y-P54170 | - | 48.0 | 36.0 | P5417 | ≤540 | |

Main component materials of gate valves for high temperature and high pressure electric power stations

Part name | Material grade | ||

valve body | WCB | WC6 | WC9 |

Valve plate | WCB | WC6 | WC9 |

bonnet | 25 | 12Cr1Mo1VA | |

valve stem | 1Cr17Ni2 | 20Cr1Mo1VA | |

valve seat | 25 | 12Cr1Mo1VA | |

Sealing ring | S soft steel (reinforced flexible graphite) | S soft steel | F soft steel |

filler | Enhanced flexible graphite | ||

support | WCB | WCB或WC6 | |

stem nut | 45(ZCuZn25A16Fe3Mn3) | ||

pendant collet | 1Cr13 | 20Cr1MoVA | |

Main external dimensions of gate valves for high temperature and high pressure electric power stations

Nominal Diameter | Main external dimensions and connection dimensions (mm) | motor unit | weight/(kg) | ||||

d | L | H | L1 | L2 | |||

Z960Y-250 | |||||||

100 | 84 | 406 | 1164 | 437 | 277 | DZW45 | 234 |

125 | 100 | 483 | 1402 | 437 | 277 | DZW60 | 343 |

175 | 158 | 711 | 1650 | 554 | 309 | DZW180 | 638 |

225 | 200 | 864 | 1650 | 554 | 309 | DZW180 | 654 |

300 | 280 | 1067 | 2106 | 764 | 398 | DZW350 | 1973 |

Z960Y-320 | |||||||

100 | 96 | 533 | 1236 | 437 | 277 | DZW60 | 291 |

125 | 118 | 610 | 1302 | 437 | 277 | DZW60 | 315 |

150 | 148 | 762 | 1403 | 526 | 283 | DZW90 | 672 |

175 | 148 | 762 | 1650 | 554 | 309 | DZW180 | 684 |

225 | 222 | 1041 | 1650 | 554 | 309 | DZW180 | 696 |

Z960Y-P54100V | |||||||

175 | 148 | 762 | 1650 | 554 | 309 | DZW180 | 683 |

225 | 222 | 1041 | 1650 | 554 | 309 | DZW180 | 704 |

250 | 222 | 1041 | 1795 | 554 | 309 | DZW180 | 1214 |

300 | 294 | 1245 | 2080 | 554 | 309 | DZW250 | 2125 |

Z960Y-P54170V | |||||||

125 | 98 | 630 | 1230 | 437 | 277 | DZW60 | 312 |

225 | 186 | 1060 | 1680 | 554 | 309 | DZW180 | 1401 |

300 | 278 | 1397 | 2265 | 764 | DZW500 | 2834 | |

325 | 310 | 1448 | 2265 | 690 | 398 | DZW500 | 2632 |

350 | 338 | 1550 | 2536 | 715 | DZWC-4 | ||

Tel: 15351513006

Landline: 0515-89118577

Fax: 0515-8911 8000

Email: jtongcn 126.com

Address: Oubei Pump and Valve Industrial Park, Binhai Economic Development Zone, Jiangsu Province

15351513006