The Z641 series pneumatic wedge gate valve is a low support rising stem gate valve with a pneumatic actuator(double-layer cylinder with buffer mechanism)and a manual and its protective mechanism(manual and self-locking pneumatic manual conversion device).Due to its double-layer cylinder structure,this valve has twice the lifting force compared to single cylinder pneumatic gate valves.This fundamentally solves the problem of some valve bodies of single cylinder pneumatic gate valves being wedged and unable to open.Moreover,due to the buffering mechanism of the valve,it can effectively reduce the wear and tear on the sealing surface of the valve plate and valve body caused by the downward impact of the piston when closing the valve.At the same time,it can also avoid the phenomenon of the gate plate getting stuck.

In order to cooperate with users to achieve operational automation,in addition to supplying this series of products,our company can also provide separate cylinder blocks including brackets to help users modify a wide variety of existing manual gate valves.By installing the dual cylinder pneumatic actuator part on the valve body cover of the manual gate valve,a dual cylinder pneumatic manual dual-purpose gate valve can be formed.

Because of its advanced technology,reliable performance,convenient operation,switching and maintenance,it has been widely used as a pipeline switching device for transporting gas and liquid media by petroleum,chemical,metallurgical,electric power,maritime and other departments.

Structural characteristics of pneumatic flange gate valve

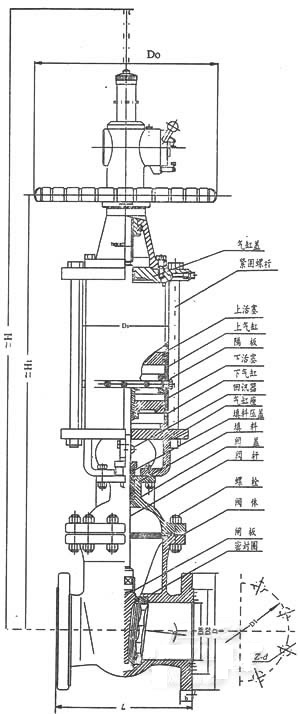

1.This valve mainly consists of a valve body,a valve cover,a gate plate,a valve stem,a sealing ring,a double-layer cylinder and its piston,a piston rod,a diaphragm,a buffer mechanism,a manual mechanism,a pneumatic manual conversion device,and a valve cover packing device.

2.When the upper piston reaches the upper end of the stroke,it can push the upper feedback device to send a signal;The lower end of the stroke of the lower piston can push down the lower return indicator to send a signal,which will be displayed on the analog instrument panel in the central operating room as the opening and closing information of the gate valve.

3.The upward and downward movement of the outward extending indicator rod on the upper part of the handwheel indicates whether the gate of the valve is in a raised or lowered state.When the gate valve is closed,the extended indicator rod is in the low position;On the contrary,when the gate valve is fully opened,the extended indicator rod is in the high position.This is the on-site indication of the opening and closing status of this valve.

4.The upper part of the cylinder head is equipped with a pneumatic manual conversion device.Turn the conversion handle clockwise to the"pneumatic"positioning hole,and the gate valve is in the pneumatic operation state;On the contrary,by turning the conversion handle counterclockwise to the"manual"position at the hole,the gate valve can be manually operated.The handle with bevel gear changes direction in the opposite direction.When manually operating a gate valve,the handwheel rotates in the same direction as a regular manual valve,clockwise to close and counterclockwise to open.The opposite rotation of bevel gears.

Main performance parameters of pneumatic flange gate valve

Nominal pressure:1.6,2.5.4,0.6.4 MPa

Operating temperature:-29~425℃(carbon steel)-40~+550℃(stainless steel)

Nominal diameter:DN50~800mm

Valve body material:304.306.316L WCB.HT200

Connecting flange:JB/T79.GB913.HG20592

Applicable media:air,water,steam,oil,and corrosive fluids such as nitric acid and acetic acid

Function mode:cutting type,adjusting type,manual control

Power supply voltage:220VAC,24VAC

Input signal:4~20mA/1~5VDC

0~20mA/0~10VDC

model | Z6S41H-25 | Z6S41H-16 | Z6S41T-10 |

Nominal Diameter DN(mm) | 50~600 | 40~400 | 40~400 |

Applicable Medium | Water, steam, oil products | Water and steam | Water and steam |

High medium temperature (℃) | 425 | 425 | 200 |

Cylinder working pressure (gauge) MPa | 0.4~0.6 | ||

Structural principle of pneumatic flange gate valve

This series of products uses purified compressed air at a working pressure of 0.4-0.6MPa(gauge pressure)to push the piston and drive the gate to move perpendicular to the fluid,achieving the purpose of opening and closing the valve.

Cleverly designed double-layer cylinder and buffer mechanism

The working principle of the double-layer cylinder and buffer mechanism is described as follows according to the four stages of gate operation:

1.Before the gate valve is opened,the piston of the upper cylinder(hereinafter referred to as the upper piston)and the piston of the lower cylinder(hereinafter referred to as the lower piston)are simultaneously subjected to force.The valve stem,under the push of the upper and lower pistons,overcomes the large static friction between the sealing surface of the gate plate and the sealing surface of the valve body with nearly twice the lifting force of a single piston,and drives the gate plate to rise.Compressed air flows from the lower chamber of the upper cylinder,passes through a specific channel set in the partition,and reaches the lower chamber of the lower cylinder through a connecting pipe,pushing the upper and lower pistons to work simultaneously.The gas in the upper chamber of the lower cylinder passes through another specific channel set inside the partition.Smooth and unobstructed discharge from the cylinder body.

2.The later stage of gate valve opening:After the gate valve is slightly opened,the lower piston runs to the top dead center,and the gate valve continues to lift under the drive of the upper piston until it reaches the fully open position.

3.The pre closing stage of the gate valve:Under the push of the upper piston,the gate leaves the fully open position and begins to descend.

4.The later stage of closing the gate:When the upper piston touches the lower piston protrusion and drives the lower piston to continue descending together,due to the obstruction of the intake channel of the upper chamber of the lower cylinder and the exhaust channel of the lower chamber of the lower cylinder,the downward speed is significantly slowed down,and the gate descends to the fully closed position.Slowing down the impact of the gate plate's downward movement,the valve can be closed tightly on its own without causing the valve plate wedge to become too tight.At the same time,it also protects the sealing surface from damage caused by violent impact.A flexible and reliable pneumatic manual conversion mechanism,equipped with a pneumatic manual conversion mechanism on the upper part of the cylinder head.At any position during the opening and closing process of the gate valve,the operating handle can be easily rotated to directly switch from pneumatic to manual or from manual to pneumatic operation.The conversion operating handle adopts a positioning pin self-locking design,and after the handle is positioned,it is reliable and stable.When the solenoid valve and its control circuit or air supply system fail,it can quickly switch to manual operation mode without the need for other auxiliary tools,ensuring the normal operation of the circuit and avoiding accidents.Before the completion of the self-control system in the new construction project,this series of gate valves can be reliably used as manual gate valves,with flexible and agile movements.

The closing time of the valve can be adjusted by adjusting the buffer mechanism installed on the partition,and the closing time of the gate can also be adjusted within a certain range.This valve can be equipped with an electric or pneumatic feedback device to send valve switch status information.Therefore,using this valve can achieve remote control,centralized control,and automatic control.

1.The cylinder of this valve is made of seamless steel pipe,with a corrosion-resistant hard chromium coating on the inner surface and polished treatment.It has the advantages of low friction,low corrosion resistance,high hardness,and long service life.

2.The sealing ring in the cylinder is made of nitrile rubber O-ring,which has reliable sealing performance and is easy to replace during maintenance

Performance Specification for Pneumatic Flange Gate Valve

1.Valve body performance

model | nominal pressurePN(MPa) | Valve body test pressurePN(MPa) | operation temperature(℃) | ||||||||

120 | 200 | 225 | 250 | 300 | 350 | 400 | 425 | ||||

strength test | Sealing test | Working pressureP(MPa) | |||||||||

Z6S41T-10 | 1.6 | 2.4 | 1.6 | - | 1.6 | - | 1.5 | 1.3 | 1.2 | 1.0 | 0.9 |

Z6S41H-25 | 2.5 | 3.8 | 2.5 | - | 2.5 | - | 2.3 | 2.0 | 1.8 | 1.6 | 1.4 |

Z6S41H-40 | 4.0 | 6.0 | 4.0 | - | 4.0 | - | 3.6 | 3.2 | 2.8 | 2.6 | 2.2 |

Z6S41H-64 | 6.4 | 9.6 | 6.4 | - | 6.4 | - | 5.7 | 5.2 | 4.6 | 3.8 | 3.6 |

2. Cylinder performance

model | nominal pressure PN(MPa) | Cylinder sealing test pressure PN(MPa) | Cylinder working pressure PN(MPa) |

Z6S41T-10 | 0.6 | 0.6 | 0.4~0.6 |

3. Gas consumption

[Purified compressed air pressure: 0.4MPa (table)] The one-way air consumption of the cylinder of the gate valve is calculated based on the volume of compressed air.

cylinder diameter D(mm) | 50 | 80 | 100 | 150 | 200 | 250 | 300 | 350 | 400 |

Gas consumption(m) | 0.0023 | 0.0029 | 0.0033 | 0.0084 | 0.0169 | 0.0198 | 0.0320 | 0.0636 | 0.0707 |

Main component materials of pneumatic flange gate valve

Valve body, valve cover, valve plate | cast steel |

Sealing surface of valve body and gate | alloy steel |

valve stem | stainless steel |

Double headed bolt | Steel 35 |

cylinder | No. 20 seamless steel pipe |

piston | Cast aluminum alloy |

Hand nut | bronze |

sealing ring | Asbestos rubber sheet |

Piston rings and collar rings | Oil resistant rubber O-ring |

stuffing box | Graphite asbestos rope |

Main external dimensions of pneumatic flange gate valve

PN1.6MPa external dimensions

DN | D | D2 | b | f | L | H | Ds | D0 | Z-d | Air source connector | weight/Kg |

50 | 160 | 100 | 16 | 3 | 250 | 865 | 160 | 250 | 4-18 | M12×1.25 | 42 |

80 | 195 | 135 | 20 | 3 | 280 | 1100 | 160 | 300 | 8-18 | 54 | |

100 | 215 | 155 | 20 | 3 | 300 | 1200 | 160 | 350 | 8-18 | 100 | |

150 | 280 | 210 | 24 | 3 | 350 | 1380 | 219 | 400 | 8-23 | 135 | |

200 | 335 | 265 | 26 | 3 | 400 | 1580 | 273 | 400 | 12-23 | 270 | |

250 | 405 | 320 | 30 | 3 | 450 | 1710 | 273 | 400 | 12-25 | M20×1.5 | 350 |

300 | 460 | 375 | 30 | 4 | 500 | 1880 | 325 | 500 | 12-25 | 480 | |

350 | 520 | 435 | 34 | 4 | 550 | 2180 | 426 | 500 | 16-25 | 570 | |

400 | 580 | 485 | 36 | 4 | 600 | 2325 | 459 | 550 | 16-30 | 900 | |

450 | 640 | 545 | 40 | 4 | 650 | 2570 | 500 | 550 | 20-30 | 1560 | |

500 | 705 | 608 | 44 | 4 | 700 | 2800 | 600 | 600 | 20-34 | M24×1.5 | 1820 |

600 | 840 | 718 | 48 | 5 | 800 | 3010 | 600 | 600 | 20-41 | M27×1.5 | 2850 |

PN2.5MPa external dimensions

DN | D | D1 | D2 | b | f | L | H | Ds | D0 | Z-d | Air source connector | weight/Kg |

50 | 160 | 125 | 100 | 20 | 3 | 250 | 865 | 160 | 250 | 4-18 | M12×1.25 | 42 |

80 | 195 | 160 | 135 | 22 | 3 | 280 | 1100 | 160 | 300 | 8-18 | 54 | |

100 | 230 | 190 | 160 | 24 | 3 | 300 | 1200 | 160 | 350 | 8-23 | 105 | |

150 | 300 | 250 | 218 | 30 | 3 | 350 | 1380 | 219 | 400 | 8-25 | 190 | |

200 | 360 | 310 | 278 | 34 | 3 | 400 | 1580 | 273 | 400 | 12-25 | 280 | |

250 | 425 | 370 | 332 | 36 | 3 | 450 | 1710 | 273 | 400 | 12-30 | M20×1.5 | 405 |

300 | 485 | 430 | 390 | 40 | 4 | 500 | 1880 | 325 | 500 | 16-30 | 535 | |

350 | 550 | 490 | 448 | 44 | 4 | 550 | 2180 | 426 | 500 | 16-34 | 720 | |

400 | 610 | 550 | 405 | 48 | 4 | 600 | 2325 | 459 | 550 | 16-34 | 1200 | |

450 | 660 | 600 | 555 | 50 | 4 | 650 | 2570 | 500 | 550 | 20-34 | 1910 | |

500 | 730 | 660 | 610 | 52 | 4 | 700 | 2800 | 650 | 600 | 20-41 | M24×1.5 | 2250 |

600 | 840 | 770 | 718 | 56 | 5 | 800 | 3010 | 730 | 600 | 20-41 | M27×1.5 | 3100 |

PN4.0MPa external dimensions

DN | D | D1 | D2 | b | f | L | H | Ds | D0 | Z-d | Air source connector | weight/Kg |

50 | 160 | 125 | 100 | 20 | 3 | 250 | 890 | 160 | 300 | 4-18 | M12×1.25 | 62 |

80 | 195 | 160 | 135 | 22 | 3 | 310 | 1150 | 219 | 350 | 8-18 | 130 | |

100 | 230 | 190 | 160 | 24 | 3 | 350 | 1300 | 273 | 400 | 8-23 | 155 | |

150 | 300 | 250 | 218 | 30 | 3 | 450 | 1450 | 273 | 400 | 8-25 | 240 | |

200 | 375 | 320 | 282 | 38 | 3 | 550 | 1660 | 325 | 500 | 12-30 | M20×1.5 | 280 |

250 | 445 | 385 | 345 | 42 | 3 | 650 | 1860 | 325 | 500 | 12-34 | 305 | |

300 | 510 | 450 | 408 | 46 | 4 | 750 | 2010 | 426 | 500 | 16-34 | 580 | |

350 | 570 | 510 | 465 | 52 | 4 | 850 | 2350 | 459 | 550 | 16-34 | 770 | |

400 | 655 | 585 | 535 | 58 | 4 | 950 | 2530 | 600 | 550 | 16-41 | 1260 | |

450 | 680 | 610 | 560 | 60 | 4 | 1050 | 2780 | 650 | 600 | 20-41 | M24×1.5 | 1680 |

500 | 755 | 670 | 612 | 62 | 4 | 1150 | 3100 | 730 | 600 | 20-48 | M27×1.5 | 2150 |

PN6.4MPa external dimensions

DN | D | D1 | D2 | b | L | H | Ds | D0 | Z-d | Air source connector | weight/Kg |

50 | 175 | 135 | 105 | 26 | 250 | 865 | 160 | 250 | 4-23 | M12×1.25 | 85 |

80 | 210 | 170 | 140 | 30 | 310 | 1170 | 300 | 300 | 8-23 | 125 | |

100 | 250 | 200 | 168 | 32 | 350 | 1280 | 350 | 350 | 8-25 | 178 | |

150 | 340 | 280 | 240 | 38 | 450 | 1470 | 400 | 400 | 8-34 | 305 | |

200 | 405 | 345 | 300 | 44 | 550 | 1650 | 400 | 400 | 12-34 | M20×1.5 | 410 |

250 | 470 | 400 | 350 | 48 | 650 | 1810 | 400 | 400 | 12-41 | 690 | |

300 | 530 | 460 | 412 | 54 | 750 | 1960 | 500 | 500 | 16-41 | 770 | |

350 | 595 | 525 | 475 | 60 | 850 | 2240 | 500 | 500 | 16-41 | 980 | |

400 | 670 | 585 | 525 | 66 | 930 | 2450 | 550 | 550 | 16-48 | M24×1.5 | 1970 |

Tel: 15351513006

Landline: 0515-89118577

Fax: 0515-8911 8000

Email: jtongcn 126.com

Address: Oubei Pump and Valve Industrial Park, Binhai Economic Development Zone, Jiangsu Province

15351513006