The J641H pneumatic flange globe valve adopts a double acting cylinder,which uses upper chamber intake or lower chamber intake to remotely control the valve,making it easy and flexible to operate.Cylinder media:compressed air,nitrogen.Simple structure,easy manufacturing and maintenance;Small work schedule and short opening and closing time;The sealing surface between the closing body(valve disc)and the valve seat adopts conical sealing,which has low closing force,erosion resistance,and reliable sealing.The valve seat can be a replaceable valve seat,which can be freely combined with the sealing surface material of the closing element to meet the working conditions and extend the service life.

Application Specification for J641H Pneumatic Flange Stop Valve

Design and manufacturing | GB/T12235 | |

Connection end size | Structure length | GB/T12221 |

Flange size | JB/T79 | |

Inspection and Testing | JB/T9092 | |

material | carbon steel | GB/T12229 |

stainless steel | GB/T12230 | |

alloy steel | Q/ZB66 | |

sign | GB/T12220 | |

supply of material | JB/T7928 | |

Structural characteristics of J641H pneumatic flange globe valve

1.Carefully selected materials,in compliance with relevant domestic and international standards,with a reasonable structure and beautiful appearance.

2.The sealing surface of the valve disc and seat is made of iron-based alloy or Stellite cobalt based hard alloy,which has good wear resistance,high temperature resistance,corrosion resistance,abrasion resistance,and long service life.

3.The valve stem has undergone quenching and surface nitriding treatment,providing excellent corrosion resistance and abrasion resistance.

4.Various piping flange standards and flange sealing surface types can be adopted to meet various engineering needs and user requirements.

5.The valve body material variety is complete,and the packing and gasket can be reasonably selected according to actual working conditions or user requirements,which can be suitable for various pressure,temperature,and medium working conditions.

6.The reverse seal is made by connecting the sealing seat with threads or welding austenitic stainless steel on the body,ensuring reliable sealing.The replacement of the packing can be carried out without stopping the machine,which is convenient and fast,and does not affect the operation of the system.

J641H Pneumatic Flange Stop Valve Main Component Materials

valve body | bonnet | Valve flap | sealing ring | valve stem | filler | Applicable Medium | Temperature(≤℃) |

WCB | WCB+D507MO | D577 | 2Crl3 | Flexible graphite | Water, oil, steam | 425 | |

ZGlCrl8Ni9Ti | 0Crl8Ni9Ti | Stellite6 | lCrl8Ni9Ti | PTFE | Nitric Acid | 200 | |

ZGlCrl8Ni2Mo2Ti | CF8M | lCrl8Ni2Mo2Ti | lCrl8Ni2Mo2Ti | PTFE | Phosphoric acid | 200 | |

ZG00Crl7Nil4M02 | CF3M | Stel1ite6 | 316L | PTFE | Phosphoric acid | 200 | |

ZGlCr5MO | ZGlCr5MO | Stel1ite6 | 25Cr2Mo1VA | Flexible graphite | Water, oil, steam | 550 | |

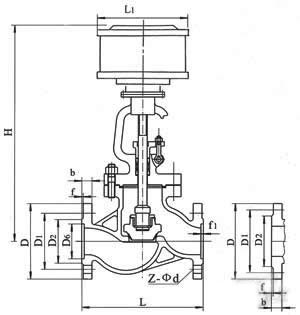

Main external dimensions of J641H pneumatic flange globe valve

nominal pressure PN(MPa) | Nominal Diameter DN(mm) | Standard value | reference value | |||||||||

L | D | D1 | n2 | D6 | b | f | f1 | Z-φd | L1 | H | ||

1.6 | 50 | 230 | 160 | 125 | 100 | 16 | 3 | 4-φ18 | 185 | 645 | ||

65 | 290 | 180 | 145 | 120 | 18 | 3 | 4-φ18 | 232 | 690 | |||

80 | 310 | 195 | 160 | 135 | 20 | 3 | 8-φ18 | 232 | 715 | |||

100 | 350 | 215 | 180 | 155 | 20 | 3 | 8-φ18 | 232 | 770 | |||

125 | 400 | 254 | 210 | 185 | 22 | 3 | 8-φ18 | 283 | 780 | |||

150 | 480 | 280 | 240 | 210 | 24 | 3 | 8-φ23 | 283 | 810 | |||

200 | 600 | 335 | 295 | 265 | 26 | 3 | 12-φ23 | 283 | 967 | |||

250 | 622 | 405 | 355 | 320 | 30 | 3 | 12-φ25 | 283 | 1143 | |||

300 | 698 | 460 | 410 | 375 | 30 | 4 | 12-φ25 | 283 | 1292 | |||

2.5 | 50 | 230 | 160 | 125 | 100 | 20 | 3 | 4-φ18 | 185 | 645 | ||

65 | 290 | 180 | 145 | 120 | 22 | 3 | 8-φ18 | 232 | 690 | |||

80 | 310 | 195 | 160 | 135 | 22 | 3 | 8-φ18 | 232 | 715 | |||

100 | 350 | 230 | 190 | 160 | 24 | 3 | 8-φ23 | 232 | 770 | |||

125 | 400 | 270 | 220 | 188 | 28 | 3 | 8-φ25 | 283 | 780 | |||

150 | 480 | 300 | 250 | 218 | 30 | 3 | 8-φ25 | 283 | 810 | |||

200 | 600 | 360 | 310 | 278 | 34 | 3 | 12-φ25 | 283 | 967 | |||

250 | 622 | 425 | 370 | 332 | 36 | 3 | 12-φ30 | 283 | 1143 | |||

300 | 698 | 485 | 430 | 390 | 40 | 4 | 16-φ30 | 283 | 1292 | |||

4.0 | 50 | 230 | 160 | 125 | 100 | 88 | 20 | 3 | 4 | 4-φ18 | 185 | 645 |

65 | 290 | 180 | 145 | 120 | 110 | 22 | 3 | 4 | 8-φ18 | 232 | 690 | |

80 | 310 | 195 | 160 | 135 | 121 | 22 | 3 | 4 | 8-φ18 | 232 | 715 | |

100 | 350 | 230 | 190 | 160 | 150 | 24 | 3 | 4.5 | 8-φ23 | 232 | 770 | |

125 | 400 | 270 | 220 | 188 | 176 | 28 | 3 | 4.5 | 8-φ25 | 283 | 782 | |

150 | 480 | 300 | 250 | 218 | 204 | 30 | 3 | 4.5 | 8-φ25 | 283 | 875 | |

200 | 600 | 375 | 320 | 282 | 260 | 38 | 3 | 4.5 | 12-φ30 | 283 | 1160 | |

Tel: 15351513006

Landline: 0515-89118577

Fax: 0515-8911 8000

Email: jtongcn 126.com

Address: Oubei Pump and Valve Industrial Park, Binhai Economic Development Zone, Jiangsu Province

15351513006