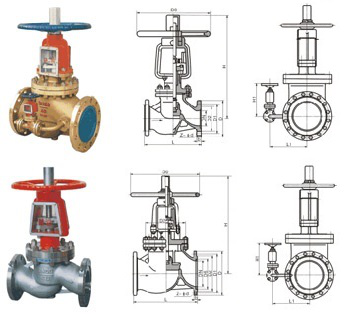

JY41W/Y oxygen shut-off valve is a specialized valve designed and manufactured based on the operating characteristics of oxygen pipelines and considering the flammable and explosive properties of oxygen media,with safety,reliability,and superior performance as the design principles,and in accordance with the provisions of the"Oxygen Safety Regulations"formulated by the Ministry of Metallurgical Industry of the People's Republic of China,to ensure the safe operation of oxygen pipelines.The main material is selected from stainless steel or copper alloy with good flame retardancy,and the sealing surface is the body or welded D802.The remaining internal components are made of stainless steel or copper alloy;The lubrication of the transmission parts adopts non flammable grease and is marked with obvious oil prohibition signs.Structurally,the bracket adopts a fully enclosed design and is equipped with a static discharge device.The valve stem is equipped with a dust cap.According to the"Several Technical Regulations for Oxygen Pipeline Networks in Steel Enterprises"issued by the Ministry of Metallurgical Industry,globe valves are used.

The main material is selected from stainless steel or copper alloy with good flame retardancy,and the sealing surface is the body or welded D802.The remaining internal components are made of stainless steel or copper alloy;The lubrication of the transmission parts adopts non flammable grease and is marked with obvious oil prohibition signs.

Structurally,the bracket adopts a fully enclosed design and is equipped with a static discharge device.The valve stem is equipped with a dust cap.

Structural characteristics of oxygen shut-off valve

1、For nominal pressures PN≥1.6MPa and DNl25-200,an internal bypass structure is adopted;DN250-500 adopts a structure with an external bypass valve.The purpose is to reduce the pressure difference between the front and back of the valve to avoid high flow rate,high erosion,and prevent high temperature,thereby ensuring the safe operation of the oxygen pipeline network and reducing the operating torque.

2、Medium flow direction:For PN≥1.6MPa and DN≤100,the medium flows from below the valve disc into above(i.e.low inlet and high outlet),while for DN≥125,the medium flows from the valve disc into below(high inlet and low outlet).For valves with DN≥125,the medium flow direction of high inlet and low outlet is adopted,which meets the structural requirements of the internal bypass valve and greatly reduces the closing force of the valve due to the pressure of the medium.

3、The valve is equipped with a static electricity safety device to prevent sparks from being generated due to static electricity.

4、Compared with ordinary shut-off valves,the support part of the shut-off valve for oxygen pipelines adopts a fully enclosed structure,and the protective cover plate on the support can be opened when the packing is compressed,which plays a role in preventing oil and dust.And there are obvious oil prohibition signs.

5、All parts undergo strict degreasing treatment

Performance parameters of oxygen shut-off valve

nominal pressure PN | strength test pressure MPa | Sealing test pressureMPa | Applicable Medium | Temperature |

water | gas | oxygen | ordinary temperature | |

1.6 | 2.4 | 1.6 | ||

2.5 | 3.8 | 2.5 | ||

3.0 | 4.5 | 3.0 | ||

4.0 | 6.0 | 4.0 |

Main component materials of oxygen shut-off valve

Part name | material |

Valve body, valve cover, valve disc | Cast chromium nickel titanium stainless steel, copper alloy |

valve stem | Chromium nickel stainless steel |

stem nut | bronze |

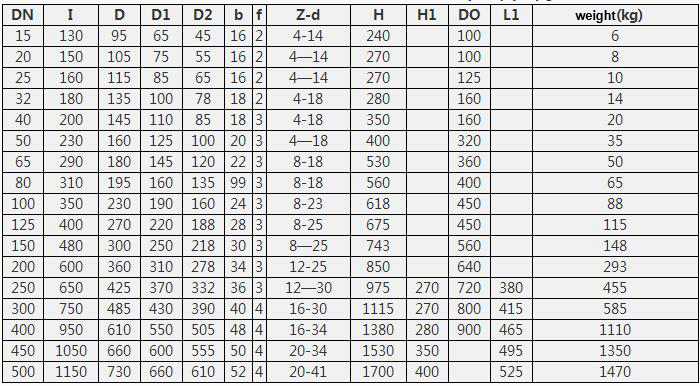

Main external dimensions of oxygen shut-off valve

JY41W-16P JY41Y-16P JY41W-16T Oxygen shut-off valve

DN | L | D | D1 | D2 | b | f | Z-d | H | H1 | DO | L1 | weight(kg) |

15 | 130 | 95 | 65 | 45 | 14 | 2 | 4-14 | 240 | 100 | 6 | ||

20 | 150 | 105 | 75 | 55 | 14 | 2 | 4-14 | 270 | 100 | 8 | ||

25 | 160 | 115 | 85 | 65 | 14 | 2 | 4-14 | 270 | 125 | 10 | ||

32 | 180 | 135 | 100 | 78 | 16 | 2 | 4-18 | 280 | 160 | 14 | ||

40 | 200 | 145 | 110 | 85 | 16 | 3 | 4-18 | 350 | 160 | 20 | ||

50 | 230 | 160 | 125 | 100 | 16 | 3 | 4-18 | 400 | 320 | 35 | ||

65 | 290 | 180 | 145 | 120 | 18 | 3 | 4-18 | 530 | 360 | 50 | ||

80 | 310 | 195 | 160 | 135 | 20 | 3 | 8-18 | 560 | 400 | 65 | ||

100 | 350 | 215 | 180 | 155 | 20 | 3 | 8-18 | 618 | 450 | 80 | ||

125 | 400 | 245 | 210 | 185 | 99 | 3 | 8-18 | 675 | 450 | 106 | ||

150 | 480 | 280 | 240 | 210 | 24 | 3 | 8-23 | 743 | 560 | 125 | ||

200 | 600 | 335 | 295 | 265 | 26 | 3 | 12-23 | 850 | 640 | 254 | ||

250 | 650 | 405 | 355 | 320 | 30 | 3 | 12-25 | 975 | 270 | 720 | 380 | 418 |

300 | 750 | 460 | 410 | 375 | 30 | 4 | 12-25 | 1115 | 270 | 800 | 415 | 502 |

400 | 950 | 580 | 525 | 485 | 36 | 4 | 16-30 | 1380 | 280 | 900 | 465 | 980 |

450 | 1050 | 640 | 585 | 545 | 40 | 4 | 20-30 | 1530 | 350 | 495 | 1200 | |

500 | 1150 | 705 | 650 | 608 | 44 | 4 | 20-34 | 1700 | 400 | 525 | 1300 |

JY41W-25P JY41Y-25P JY41W-25T oxygen stop 38400400;

Tel: 15351513006

Landline: 0515-89118577

Fax: 0515-8911 8000

Email: jtongcn 126.com

Address: Oubei Pump and Valve Industrial Park, Binhai Economic Development Zone, Jiangsu Province

15351513006