Q41H metal hard seal ball valve is a high-performance ball valve product developed by our company.The valve seat adopts a metal sealing structure loaded with leaf springs,which can be easily opened and closed at high temperatures.The sphere and valve seat are treated with special hardening,and the sealing surface is not scratched.The manual hard seal ball valve has bidirectional sealing function.Main application:Metal hard seal ball valves are used on various pipelines with working temperatures of-29~425℃(carbon steel)or-40~550℃(stainless steel)to cut off or connect media in pipelines.Different materials are selected,and metal hard seal ball valves can be applied to various media such as water,steam,oil,nitric acid,acetic acid,oxidizing media,urea,etc.

Characteristics of Metal Hard Sealed Ball Valve Products

1.Advanced valve seat:The valve seat is designed based on years of experience in ball valve manufacturing,ensuring valve sealing,low friction coefficient,small operating torque,multiple valve seat materials,and wide adaptability.

2.Accurate switch handle:Using a flat head valve stem,the connection with the handle will not be misaligned,ensuring that the switch status indicated by the handle is consistent with the valve.

3.Locking device:To prevent misoperation of valve opening and closing,there are locking holes in the fully open and fully closed positions of the valve to ensure that it is in the correct position.

4.Valve stem anti flying structure:The valve stem is bottom mounted to prevent it from flying out under pressure,and can also form metal contact with the valve body after a fire,ensuring the valve stem is sealed.

Design Specification for Metal Hard Seal Ball Valve

Design and Manufacturing Standards | GB/T 21385-2008 |

Structural length standard | B/T 12221-2005 |

Connection flange standard | GB/T 9113、ANSI B16.5、JB/T74~90、GB9112~9131、 HG20615~20635、SH3406 |

Pressure and temperature rating | GB/T 12224-2005 |

Test and Inspection Standards | GB/T 13927-2008 |

Performance specification for metal hard sealed ball valves

pressure rating | nominal pressure | Pound level | ||||||||

1.6 | 2.5 | 4.0 | 6.4 | 10.0 | 150 | 300 | 400 | 600 | ||

test pressure | Shell Test | 2.4 | 3.75 | 6.0 | 9.6 | 15.0 | 3.03 | 7.5 | 10.2 | 15.0 |

Sealing test | 1.76 | 2.75 | 4.4 | 7.04 | 11.0 | 2.2 | 5.5 | 7.48 | 11.0 | |

Applicable working conditions | Applicable Medium | Pulp, slurry, dust, and various solid particle media | ||||||||

Temperature | -196~≤550℃ | |||||||||

Applicable specifications | Design and manufacturing according to | GB12237-89 API60 JP17S-48 | ||||||||

Flange size according to | JB79-59、GB91133、HG20592-97 ANSI B16.5 JIS B2212-2214 | |||||||||

Structure length according to | GB12221-89 ANSI B16.0 JIS B2002 | |||||||||

Inspection and testing according to | JB/T9092-99 API598 | |||||||||

Main component materials of metal hard sealed ball valve

Serial Number | Part name | material quality | Serial Number | Part name | material quality | ||

GB(national standard) | ASTM(American Standard) | GB(national standard) | ASTM(American Standard) | ||||

1 | valve body | WCB | A216-WCB | 8 | spring | 60Si2Mn | AISI 9260 |

2 | sealing ring | Flexible graphite | Flexible graphite | 9 | shim | Flexible graphite+stainless steel | B12.10-304/F.G |

3 | valve seat | 1Cr18Ni9Ti | 304 | 10 | filler | Flexible graphite | Flexible graphite |

4 | sphere | 1Cr13 | A276-420 | 11 | Packing gland | WCB | A216-WCB |

5 | nut | 35 | A194-2H | 12 | RING | 65Mn | AISI 1066 |

6 | Stud | 35CrMoA | A193-B7 | 13 | valve stem | 1Cr13 | A276-410 |

7 | cushion | 1Cr18Ni9Ti | 304 | 14 | screw | 35 | A193-B7 |

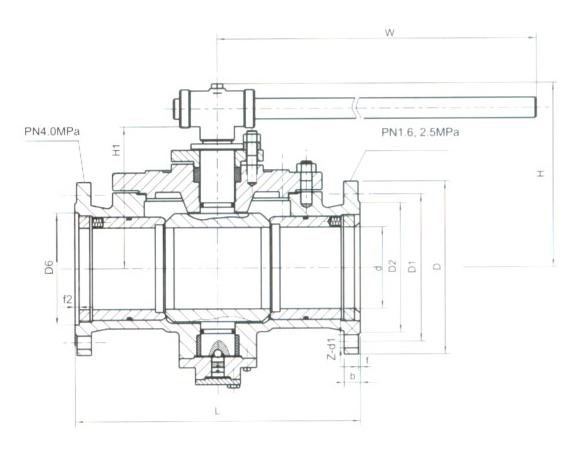

Main external dimensions of metal hard sealed ball valve

PN1.6MPa external dimensions

Nominal DiameterDN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | |||||

L | 130 | 140 | 150 | 165 | 180 | 200 | 220 | 250 | 280 | 320 | 360 | 400 | |||||

H | 59 | 63 | 75 | 85 | 95 | 107 | 142 | 152 | 178 | 252 | 272 | 342 | |||||

W | 130 | 130 | 160 | 180 | 230 | 230 | 400 | 400 | 650 | 1050 | 1050 | 1410 | |||||

D、D1、D2 | Production shall be carried out in accordance with national standards such as GB/T9113, JB/T79, HG20594, etc | ||||||||||||||||

Wt(Kg) | 2.5 | 3 | 5 | 6 | 7 | 10 | 15 | 19 | 33 | 58 | 93 | 160 | |||||

Flange connection size | GB/T9113、JB/T79、HG/T20594 | ||||||||||||||||

PN2.5MPa external dimensions

Nominal Diameter DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 |

L | 130 | 140 | 150 | 165 | 180 | 200 | 220 | 250 | 320 | 400 | 400 | 550 |

H | 59 | 63 | 75 | 97 | 107 | 142 | 152 | 178 | 252 | 272 | 342 | 345 |

W | 130 | 130 | 160 | 230 | 230 | 400 | 400 | 700 | 1100 | 1100 | 1500 | 1500 |

Wt(Kg) | 2.5 | 3 | 5 | 6 | 7.5 | 10 | 15 | 20 | 33 | 60 | 93 | 175 |

Flange connection size | GB/T9113、JB/T79、HG/T20594 | |||||||||||

PN4.0MPa external dimensions

Nominal Diameter DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 |

L | 130 | 140 | 150 | 180 | 200 | 220 | 250 | 280 | 320 | 400 | 400 | 400 |

H | 59 | 63 | 75 | 85 | 95 | 107 | 142 | 152 | 178 | 252 | 272 | 342 |

W | 130 | 130 | 160 | 230 | 230 | 400 | 400 | 700 | 1100 | 1100 | 1500 | 1500 |

Wt(Kg) | 3 | 4 | 5 | 7 | 9 | 12 | 18 | 28 | 46 | 75 | 106 | 190 |

Flange connection size | GB/T9113、JB/T79、HG/T20594 | |||||||||||

PN6.4MPa external dimensions

Nominal Diameter DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 |

L | 165 | 190 | 216 | 229 | 241 | 292 | 330 | 356 | 432 | 508 | 559 | 660 |

H | 59 | 63 | 75 | 97 | 107 | 142 | 152 | 178 | 252 | 272 | 305 | 398 |

W | 130 | 130 | 160 | 230 | 230 | 400 | 400 | 700 | 1100 | 1100 | 1500 | 1800 |

Wt(Kg) | 6.5 | 7 | 8 | 12 | 14 | 18 | 28 | 40 | 65 | 98 | 140 | 250 |

Flange connection size | GB/T9113、JB/T79、HG/T20594 | |||||||||||

Tel: 15351513006

Landline: 0515-89118577

Fax: 0515-8911 8000

Email: jtongcn 126.com

Address: Oubei Pump and Valve Industrial Park, Binhai Economic Development Zone, Jiangsu Province

15351513006