Q47F fixed ball valve/Q647F pneumatic fixed ball valve/Q947F electric fixed ball valve is a new generation of high-performance ball valves, suitable for long-distance pipelines and general industrial pipelines. Its strength, safety, and resistance to harsh environments have been specially considered in the design, and it is suitable for various corrosive and non corrosive media. Compared with floating ball valves, during operation, all the force generated by the fluid pressure in front of the valve on the ball is transmitted to the bearing, which will not cause the ball to move towards the valve seat, so the valve seat will not bear excessive pressure. Therefore, fixed ball valves have smaller torque, smaller valve seat deformation, stable sealing performance, and longer service life, making them suitable for high-pressure and large-diameter applications. Advanced spring pre seat components with self tightening characteristics achieve upstream sealing. Each valve has two valve seats, which can seal in each direction, so there is no flow restriction during installation, and it is a two-way flow.

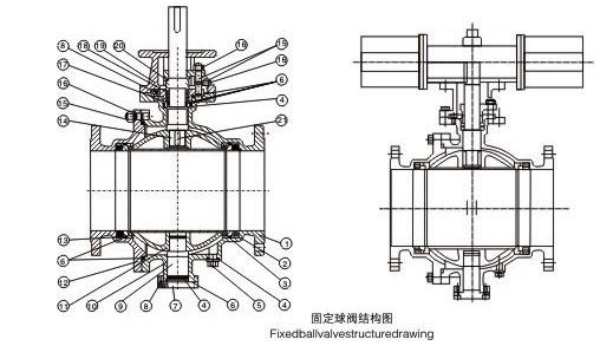

The Q47F fixed ball valve has two types of valve body structures: two-piece and three piece. The middle flange is connected by bolts, and the seal is made of reinforced polytetrafluoroethylene embedded in a stainless steel ring. There is no spring at the back of the steel ring to ensure that the valve seat is tightly attached to the ball, maintaining a seal. There are no PTFE bearings on both the upper and lower valve stems, reducing friction and making operation effortless. There are no adjustment plates at the bottom of the small shaft to ensure the joint position between the ball and the sealing ring. Full bore: The valve flow aperture is consistent with the inner diameter of the pipeline for pipeline cleaning.

Applicable media: water, gas, oil, natural gas, and acid-base corrosive media.

Applicable temperature: -196~350 ℃

Drive modes: manual, pneumatic, electric, hydraulic, etc.

Nominal diameter: DN25-8001 "~32"

Characteristics of fixed ball valve products

(1) Effortless operation: The ball is supported by upper and lower bearings, reducing friction and eliminating excessive torque caused by the huge sealing load formed by the inlet pressure pushing the ball and the sealing seat.

(2) Reliable sealing performance: The PTFE single sex material sealing ring is embedded in the stainless steel valve seat, and the metal valve seat end is equipped with a spring to ensure sufficient pre tightening force of the sealing ring. When the sealing surface of the valve wears out during use, the valve continues to ensure good sealing performance under the action of the spring.

(3) Fireproof structure: In order to prevent the PTFE sealing ring from burning out due to sudden heat or fire, causing significant leakage and fueling the fire, a fireproof sealing ring is installed between the sphere and the valve seat. When the sealing ring burns out, the valve seat sealing ring is quickly pushed onto the sphere by the spring force, forming a metal to metal seal and achieving a certain degree of sealing effect. The fire resistance test meets the requirements of APl6FA and APl607 standards.

(4) Automatic pressure relief function: When the pressure of the stagnant medium in the valve chamber abnormally increases beyond the preload force of the spring, the valve seat will retract and detach from the ball, achieving the effect of automatic pressure relief. After pressure relief, the valve seat will automatically reset.

(5) Drain pipeline: Drain plugs L are installed on both the upper and lower parts of the valve body to check if there is any leakage in the valve seat. During operation, when the valve is fully open or fully closed, the pressure in the middle chamber can be relieved and the packing can be directly replaced; It can discharge the retained substances in the middle chamber and reduce the pollution of the medium to the valve. Auxiliary sealing setting system (please specify when ordering)

(6) This valve is designed with an auxiliary seat emergency sealing system. Once the seal is damaged or an emergency situation occurs and cannot be sealed, the corresponding sealing agent can be injected into the sealing surface through the auxiliary sealing system to repair the sealing surface and achieve emergency sealing. When the conveyed medium is unclean or contains a small amount of particles, in order to protect the sealing surface and ensure reliable sealing, corresponding cleaning agents or lubricants can be injected into this device to clean the sealing surface.

(7) Electric fixed ball valves are widely used for cutting off or circulating media in transportation pipelines such as food, medicine, petroleum, chemical, natural gas, steel, environmental protection, and papermaking. Corresponding cleaning agents or lubricants can also be injected into this device to clean the sealing surface.

Technical specifications for fixed ball valves

Design basis | National standard series | American standard series | |

Design standards | GB/T12237 | AP16D | ANSI B16.34 |

Length of flange connection structure | GB/T12221 | AP16D | ANSI B16.10 |

Structural length (welding) | GB/T15188.1 | AP16D | ANSI B16.10 |

Connecting flange | GB/T9113 | ANSI B16.5、B16.47 | |

Welding end | GB/T12224 | ANSI B16.25 | |

Testing and Inspection | GB/T9092 | AP16D | AP1598 |

Fixed ball valve pressure test

pressure rating | Test pressure (MPa) | ||

nominal pressure(PN) | Pound level(Class) | Shell Test | Sealing test |

1.0 | - | 1.5 | 1.1 |

1.6 | - | 2.5 | 1.76 |

2.5 | - | 3.8 | 2.75 |

4.0 | - | 6.0 | 4.4 |

6.4 | - | 9.6 | 7.04 |

- | 150 | 3.0 | 2.2 |

- | 300 | 7.6 | 5.6 |

- | 600 | 15.0 | 11.0 |

- | 10K | 2.4 | 1.5 |

- | 20K | 5.8 | 4.0 |

Main component materials of fixed ball valve

Serial Number | Part name | material quality | |

GB | ASTM | ||

1 | valve body | WCB | A2116-WCB |

2 | spring | 60Si2aMn | AISI 9260 |

3 | sealing ring | PTFE | PTFE |

4 | shim | PTFE | PTFE |

5 | Discharge nut | 25 | A105 |

6 | "0" O-ring | rubber | rubber |

7 | bottom | 25 | A105 |

8 | screw | 35 | A193-B7 |

9 | stationary shaft | 1Cr13 | A276-410 |

10 | sliding bearing | PTFE& | PTFE& |

11 | sphere | 1C18Ni9Ti | SS304 |

12 | bonnet | WCB | A216-WCB |

13 | valve seat | 25 | A105 |

14 | valve stem | 1Cr33 | A276-410 |

15 | Stud | 35CrMoA | A193-B7 |

16 | nut | 35 | A194-2H |

17 | Gland | 25 | A105 |

18 | filler | PTFE | PTFE |

19 | support | WCB | A216-WCB |

20 | Packing gland | WCB | A2116-WCB |

21 | Key | 45 | AISI C 1045 |

Main external dimensions of fixed ball valve/pneumatic fixed ball valve/electric fixed ball valve

PN1.6MPa external dimensions

Nominal DiameterDN | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 700 | |

d1 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 337 | 387 | 438 | 489 | 591 | 686 | |

L | 165 | 180 | 190 | 216 | 241 | 283 | 305 | 356 | 394 | 457 | 533 | 610 | 686 | 762 | 864 | 914 | 1067 | 1245 | |

H | 50 | 55 | 80 | 102 | 114 | 127 | 152 | 184 | 219 | 273 | 360 | 395 | 430 | 470 | 550 | 580 | 700 | 800 | |

hand movement | H1 | 75 | 85 | 95 | 107 | 125 | 152 | 178 | 300 | 330 | 398 | 495 | 580 | 625 | 670 | 698 | 840 | 1050 | 1100 |

E | - | - | - | - | - | - | - | - | - | 116 | 116 | 171 | 171 | 257 | 257 | 257 | 150 | 83 | |

F | - | - | - | - | - | - | - | - | - | 350 | 350 | 400 | 420 | 400 | 420 | 400 | 410 | 650 | |

W | 160 | 160 | 230 | 230 | 400 | 400 | 650 | 1050 | 1050 | 600 | 600 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | |

Wt(Kg) | 4.5 | 5.7 | 7.0 | 12 | 16 | 22 | 35 | 58 | 74 | 205 | 322 | 460 | 576 | 864 | 1280 | 1600 | 1600 | 4500 | |

electric | H2 | - | - | - | - | - | - | - | - | 554 | 600 | 652 | 760 | 770 | 830 | - | 940 | 940 | 1115 |

L1 | - | - | - | - | - | - | - | - | 235 | 235 | 235 | 259 | 400 | 400 | - | 410 | 410 | 410 | |

pneumatic | H3 | 215 | 240 | 264 | 274 | 379 | 389 | 479 | 552 | 666 | 736 | 926 | 1059 | 1127 | 1393 | 1468 | 1538 | 1538 | 1450 |

L2 | 200 | 270 | 270 | 270 | 405 | 405 | 576 | 576 | 776 | 776 | 776 | 1060 | 1060 | 1360 | 1360 | 1360 | 1360 | 2840 | |

PN2.5MPa external dimensions

Nominal DiameterDN | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 700 | |

d1 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 337 | 387 | 438 | 489 | 591 | 686 | |

L | 165 | 180 | 190 | 216 | 241 | 283 | 305 | 381 | 403 | 502 | 568 | 648 | 762 | 838 | 914 | 991 | 1143 | 1346 | |

H | 50 | 55 | 80 | 102 | 114 | 127 | 152 | 184 | 219 | 273 | 360 | 395 | 430 | 470 | 550 | 580 | 700 | 800 | |

hand movement | H1 | 75 | 85 | 95 | 107 | 125 | 152 | 178 | 300 | 330 | 398 | 495 | 580 | 625 | 670 | 698 | 840 | 1050 | 1100 |

E | - | - | - | - | - | - | - | - | - | 116 | 116 | 171 | 171 | 257 | 257 | 257 | 150 | 83 | |

F | - | - | - | - | - | - | - | - | - | 350 | 350 | 420 | 420 | 400 | 400 | 400 | 410 | 650 | |

W | 160 | 160 | 230 | 230 | 400 | 400 | 650 | 1050 | 1050 | 600 | 600 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | |

Wt(Kg) | 4.5 | 5.7 | 7.0 | 15 | 24 | 30 | 55 | 87 | 118 | 255 | 370 | 533 | 640 | 1030 | 1524 | 2100 | 4200 | 5300 | |

electric | H2 | - | - | - | - | - | - | - | - | 235 | 235 | 400 | 400 | 410 | 410 | - | 420 | 690 | 690 |

L1 | - | - | - | - | - | - | - | - | 74 | 350 | 350 | 420 | 420 | 400 | - | 400 | 410 | 650 | |

pneumatic | H3 | 215 | 240 | 264 | 340 | 379 | 452 | 479 | 646 | 666 | 814 | 1002 | 1059 | 1150 | 1205 | 1250 | 1295 | 1390 | 1470 |

L2 | 200 | 270 | 270 | 405 | 405 | 574 | 574 | 756 | 756 | 1060 | 1060 | 1060 | 1360 | 1360 | 2840 | 2840 | 3300 | 3300 | |

PN4.0MPa external dimensions

Nominal DiameterDN | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 700 | |

d1 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 337 | 387 | 438 | 489 | 591 | 686 | |

L | 165 | 180 | 190 | 216 | 241 | 283 | 305 | 381 | 403 | 502 | 568 | 648 | 762 | 838 | 914 | 991 | 1143 | 1346 | |

H | 50 | 55 | 80 | 102 | 114 | 127 | 152 | 184 | 219 | 273 | 360 | 395 | 430 | 470 | 550 | 580 | 700 | 800 | |

hand movement | H1 | 75 | 85 | 95 | 107 | 125 | 152 | 178 | 300 | 330 | 398 | 495 | 580 | 625 | 670 | 698 | 840 | 1050 | 1100 |

E | - | - | - | - | - | - | - | - | - | 116 | 116 | 171 | 171 | 257 | 257 | 257 | 150 | 83 | |

F | - | - | - | - | - | - | - | - | - | 350 | 350 | 420 | 420 | 400 | 400 | 400 | 410 | 650 | |

W | 160 | 160 | 230 | 230 | 400 | 400 | 650 | 1050 | 1050 | 600 | 600 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | |

Wt(Kg) | 4.5 | 5.7 | 7.0 | 15 | 24 | 30 | 55 | 87 | 118 | 255 | 370 | 533 | 640 | 1030 | 1524 | 2100 | 4200 | 5300 | |

electric | H2 | - | - | - | - | - | - | - | - | 235 | 235 | 400 | 400 | 410 | 410 | - | 420 | 690 | 690 |

L1 | - | - | - | - | - | - | - | - | 74 | 350 | 350 | 420 | 420 | 400 | - | 400 | 410 | 650 | |

pneumatic | H3 | 215 | 240 | 264 | 340 | 379 | 452 | 479 | 646 | 666 | 814 | 1002 | 1059 | 1150 | 1205 | 1250 | 1295 | 1390 | 1470 |

L2 | 200 | 270 | 270 | 405 | 405 | 574 | 574 | 756 | 756 | 1060 | 1060 | 1060 | 1360 | 1360 | 2840 | 2840 | 3300 | 3300 | |

Tel: 15351513006

Landline: 0515-89118577

Fax: 0515-8911 8000

Email: jtongcn 126.com

Address: Oubei Pump and Valve Industrial Park, Binhai Economic Development Zone, Jiangsu Province

15351513006