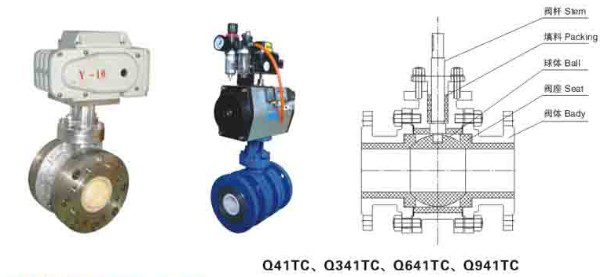

Q41TC ceramic ball valve/Q341TC worm gear ceramic ball valve Q641TC pneumatic ceramic ball valve/Q941TC electric ceramic ball valve have significant characteristics such as strong corrosion resistance,high temperature resistance,wear resistance,and erosion resistance.Widely used in various acid-base salt gas,liquid,high-temperature steam,and mud transportation systems in industries such as petrochemicals,metallurgy,papermaking,power plants,and oil refining.It is an ideal substitute for titanium metal valves and Monel valves in highly corrosive environments.Zirconia ceramic ball valves have the advantages of low cost,high operating economy,and long service life(2-4 times that of titanium valves).Its driving methods include manual,pneumatic,pneumatic spring reset,electric,etc.And various special ceramic valves can be designed according to user requirements.Suitable for various acidic,alkaline,salt liquid,and gas media environments,hard sealed valves are particularly suitable for environments with particles and fibrous media.

characteristic

1.All parts in contact with the medium are made of structural ceramic materials,which have high chemical stability and hardness(Rockwell hardness HRC90),second only to diamond.Therefore,ceramic ball valves have high wear resistance,corrosion resistance,erosion resistance,good insulation,and low thermal expansion.

2.The sphere is manufactured using advanced grinding equipment and processes,with high roundness accuracy and good surface quality.After being aligned with the valve seat,it can achieve good sealing performance by utilizing the self lubrication of Zr02 ceramic.

3.The excellent wear resistance of ceramics makes this valve durable,highly reliable,and has a long service life,which is 2-4 times that of titanium alloy valves and Monel valves.

4.This valve has unparalleled advantages and is currently suitable for high hardness granular media or media with soft particles but corrosion.

Ceramic ball valve main component materials

valve body | valve stem | sphere | valve seat | filler | Applicable Medium | Temperature |

WCB | 2Cr13 | Composite ceramics | Composite ceramics | PTFE | Corrosive media such as coal powder, coal slag, and powdery particles | ≤200℃ |

CF8 | 0Cr18Ni9 | Composite ceramics | Composite ceramics | PTFE | Coal powder, coal slag, powdered particles, and corrosive media such as urea | ≤200℃ |

CF8M | 0Cr17Ni12Mo2 | Composite ceramics | Composite ceramics | PTFE | Corrosive media such as coal powder, coal slag, powdered particles, nitric acid, etc | ≤200℃ |

CF3M | 00Cr17Ni14Mo2 | Composite ceramics | Composite ceramics | PTFE | Corrosive media such as coal powder, coal slag, powdered particles, and acetic acid | ≤200℃ |

Ceramic Ball Valve Design Standards

Design basis | GB | API | ASME |

Design standards | GB/T12237 | API6D | ASME B16.34 |

Structure length | GB/T12221 | API6D | ASME B16.10 |

Connecting flange | GB/T9113 JB/T79 | ASME B16.5、B16.47 | |

Testing and Inspection | JB/T9092 | API6D | API598 |

Ceramic ball valve test pressure

nominal pressurePN | Normal working pressure at room temperature | Shell Test Pressure | air tight test pressure | High pressure sealing test pressure |

1.6 | 1.6 | 2.4 | 0.6 | 1.76 |

2.5 | 2.5 | 3.8 | 0.6 | 2.75 |

4 | 4 | 6 | 0.6 | 4.4 |

6.4 | 6.4 | 9.6 | 0.6 | 7.1 |

Class150 | 2 | 3 | 0.6 | 2.2 |

Class300 | 5 | 7.5 | 0.6 | 5.5 |

Main connection dimensions of ceramic ball valve

model | PN | Main dimensions (mm) | |||||||

DN | D | D1 | D2 | b | f | L | n-d | ||

Q41TC Q341TC Q641TC Q941TC | 1.0MPa | 15 | 95 | 65 | 45 | 14 | 2 | 130 | 4×14 |

20 | 105 | 75 | 55 | 16 | 2 | 130 | 4×14 | ||

25 | 115 | 85 | 65 | 16 | 2 | 140 | 4×14 | ||

32 | 135 | 100 | 78 | 18 | 2 | 165 | 4×18 | ||

40 | 145 | 110 | 85 | 18 | 3 | 165 | 4×18 | ||

50 | 160 | 125 | 100 | 20 | 3 | 203 | 4×18 | ||

65 | 180 | 145 | 120 | 20 | 3 | 222 | 4×18 | ||

80 | 195 | 160 | 135 | 22 | 3 | 241 | 4×18 | ||

100 | 215 | 180 | 155 | 22 | 3 | 305 | 8×18 | ||

125 | 245 | 210 | 185 | 24 | 3 | 356 | 8×18 | ||

150 | 280 | 240 | 210 | 24 | 3 | 394 | 8×23 | ||

200 | 335 | 295 | 265 | 26 | 3 | 457 | 8×23 | ||

250 | 390 | 350 | 320 | 28 | 3 | 533 | 12×23 | ||

300 | 440 | 400 | 368 | 28 | 4 | 610 | 12×23 | ||

1.6MPa | 15 | 95 | 65 | 45 | 14 | 2 | 130 | 4×14 | |

20 | 105 | 75 | 55 | 14 | 3 | 130 | 4×14 | ||

25 | 115 | 85 | 65 | 14 | 3 | 140 | 4×14 | ||

32 | 135 | 100 | 78 | 16 | 3 | 165 | 4×18 | ||

40 | 145 | 110 | 85 | 16 | 3 | 165 | 4×18 | ||

50 | 160 | 125 | 100 | 16 | 3 | 203 | 4×18 | ||

65 | 180 | 145 | 120 | 18 | 3 | 222 | 4×18 | ||

80 | 195 | 150 | 135 | 20 | 3 | 241 | 8×18 | ||

100 | 215 | 180 | 155 | 20 | 3 | 305 | 8×18 | ||

125 | 245 | 210 | 185 | 22 | 3 | 356 | 8×18 | ||

150 | 280 | 240 | 210 | 24 | 3 | 394 | 8×22 | ||

200 | 335 | 295 | 265 | 26 | 3 | 457 | 12×22 | ||

250 | 405 | 355 | 320 | 30 | 3 | 533 | 12×25 | ||

300 | 460 | 410 | 375 | 30 | 4 | 610 | 12×25 | ||

2.5MPa | 15 | 95 | 65 | 45 | 16 | 2 | 130 | 4×14 | |

20 | 105 | 75 | 55 | 16 | 2 | 130 | 4×14 | ||

25 | 115 | 85 | 65 | 16 | 2 | 140 | 4×14 | ||

32 | 135 | 100 | 78 | 18 | 2 | 165 | 4×18 | ||

40 | 145 | 110 | 85 | 18 | 3 | 165 | 4×18 | ||

50 | 160 | 125 | 100 | 20 | 3 | 203 | 4×18 | ||

65 | 180 | 145 | 120 | 22 | 3 | 222 | 8×18 | ||

80 | 195 | 160 | 135 | 22 | 3 | 241 | 8×18 | ||

100 | 230 | 190 | 160 | 24 | 3 | 305 | 8×23 | ||

125 | 270 | 220 | 188 | 28 | 3 | 356 | 8×25 | ||

150 | 300 | 250 | 218 | 30 | 3 | 394 | 8×25 | ||

200 | 360 | 310 | 278 | 34 | 3 | 457 | 12×25 | ||

250 | 425 | 370 | 332 | 36 | 3 | 533 | 12×30 | ||

300 | 485 | 430 | 390 | 40 | 4 | 610 | 16×30 | ||

Tel: 15351513006

Landline: 0515-89118577

Fax: 0515-8911 8000

Email: jtongcn 126.com

Address: Oubei Pump and Valve Industrial Park, Binhai Economic Development Zone, Jiangsu Province

15351513006