Pneumatic O-type cut-off ball valve

It is mainly used to cut off or connect media in pipelines,and can also be used for fluid regulation and control.Compared with other valves,it has the following advantages.

characteristic

1.Low fluid resistance,ball valve is one of the types of valves with low fluid resistance,even for reduced diameter ball valves,its fluid resistance is quite small.

2.The thrust bearing reduces the friction torque of the valve stem,which can make the valve stem operate smoothly and flexibly for a long time.

3.The valve seat has good sealing performance,and the sealing ring is made of elastic materials such as polytetrafluoroethylene.The structure is easy to seal,and the sealing ability of the ball valve increases with the increase of medium pressure.

4.The valve stem seal is reliable.As the valve stem only rotates without lifting,the packing seal of the valve stem is not easily damaged,and the sealing ability increases with the pressure of the medium.

5.Due to the good self-lubricating properties of materials such as polytetrafluoroethylene,the friction loss with the ball is small,resulting in a long service life of the ball valve.

6.The bottom mounted valve stem and the protruding step at the head of the valve stem prevent the valve stem from spraying out.In the event of a fire causing damage to the valve stem seal,the protruding step can also form a metal contact with the valve body to ensure the valve stem seal.

7.Anti static function:Install springs between the ball,valve stem,and valve body to dissipate static electricity generated during the switching process.

Pneumatic O-type cut-off ball valve actuator

Adopting a new series of GT type pneumatic actuators,with double acting and single acting(spring reset),gear rack transmission,safe and reliable;The large-diameter valve adopts a series of AW type pneumatic actuator fork type transmission,with a reasonable structure and large output torque,and is available in double acting and single acting types.

1.Gear type dual piston,with large output torque and small volume.

2.The cylinder is made of aluminum material,which is lightweight and aesthetically pleasing.

3.Manual operating mechanisms can be installed at the top and bottom.

4.The rack and pinion connection can adjust the opening angle and rated flow rate.

5.The actuator can be equipped with live signal feedback indicators and various accessories to achieve automated operation.

6.The IS05211 standard connection provides convenience for the installation and replacement of products.

7.The adjustable screws at both ends provide a±4°adjustable range for standard products between 0°and 90°.Ensure synchronization accuracy with the valve

The options for attachments can be selected based on different controls and requirements,including the following attachments:

Cut off accessories:single electric control solenoid valve,dual electric control solenoid valve,limit switch feedback device.

Adjustable accessories:electrical locator,pneumatic locator,electrical converter.

Air source processing accessories:air filter pressure reducing valve,air source processing triad.

Manual mechanism:HVSD manual control mechanism

Pneumatic O-type cut-off ball valve execution standard

1.Design and Manufacturing:GB12237-89 API608、API 6D、JPI 7S-48、BS5351、DIN3357。

2.Flange size:JB/T74-90(JB74-90)GB9112~9131、HGJ44~76、SH3406、ANSI B16.5、JIS B2212~2214、NF E29-211、DIN2543。

3.Structural length:GB12221-89 ANSI B16.10、JIS B2002、NF E29-305、DIN3202。

4.Main test for inspection:JB/T 9092,API 598.

Performance Specification for Pneumatic O-Type Cut off Ball Valve

Nominal Diameter mm | DN15-DN300 | |||

MATERIAL | C | P | R | |

Main parts | valve body | WCB | ZG1Cr18Ni9Ti | ZG1Cr18Ni |

sphere | 2Cr13 | 1Cr18Ni9Ti | 1Cr18Ni12MoTi | |

Valve stem | 2Cr13 | 1Cr18Ni9Ti | 1Cr18Ni12MoTi | |

sealing ring | Enhanced polytetrafluoroethylene to polystyrene | |||

Packing material | Polytetrafluoroethylene flexible graphite | |||

Applicable working conditions | apply | Steam, water | Nitric Acid | Acetic acid |

Temperature | -28℃ - 300℃ | |||

actuator | Model | AW, DA/SR series, GTE series, TH series, etc | ||

Mpa | 0.4-0.7MPa | |||

Pneumatic O-type cut-off ball valve pressure test

test pressure(Mpa) | nominal pressure(Mpa) | pressure stage(class) | JIS(Mpa) | |||||||

1.6 | 2.5 | 4.0 | 6.4 | 10.0 | 150 | 300 | 600 | 10K | 20K | |

strength test | 2.4 | 3.8 | 6.0 | 9.6 | 15.0 | 3.1 | 7.8 | 15.3 | 2.4 | 3.8 |

Sealing test | 1.8 | 2.8 | 4.4 | 7.0 | 11.0 | 2.2 | 5.6 | 11.2 | 1.5 | 2.8 |

Air tightness test | 0.5~0.7 | |||||||||

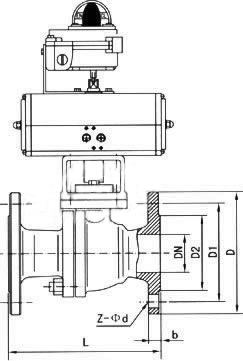

Installation dimensions of pneumatic O-type cut-off ball valve

Nominal DiameterDN(mm) | size(mm) | Model of actuator | ||||||||||||||

1.6MPa | 2.5MPa | 4.0MPa | ||||||||||||||

L | D | D1 | b | Z-фD | L | D | D1 | b | Z-фD | L | D | D1 | b | Z-фD | Optional DA/SR, QGSY | |

15 | 130 | 95 | 65 | 14 | 4-14 | 130 | 95 | 65 | 16 | 4-14 | 130 | 130 | 65 | 16 | 4-14 | |

20 | 130 | 105 | 75 | 14 | 4-14 | 130 | 105 | 75 | 16 | 4-14 | 150 | 150 | 75 | 16 | 4-14 | |

25 | 140 | 115 | 85 | 14 | 4-14 | 140 | 115 | 85 | 16 | 4-14 | 160 | 160 | 85 | 16 | 4-14 | |

32 | 165 | 135 | 100 | 16 | 4-18 | 165 | 135 | 100 | 18 | 4-18 | 180 | 180 | 100 | 18 | 4-18 | |

40 | 165 | 145 | 110 | 16 | 4-18 | 165 | 145 | 110 | 18 | 4-18 | 200 | 200 | 110 | 18 | 4-18 | |

50 | 203 | 160 | 125 | 16 | 4-18 | 203 | 160 | 125 | 20 | 4-18 | 230 | 230 | 125 | 20 | 4-18 | |

65 | 222 | 180 | 145 | 18 | 4-18 | 222 | 180 | 145 | 22 | 8-18 | 290 | 290 | 145 | 22 | 8-18 | |

80 | 241 | 195 | 160 | 20 | 8-18 | 241 | 195 | 160 | 22 | 8-18 | 310 | 310 | 160 | 22 | 8-18 | |

100 | 305 | 215 | 180 | 20 | 8-18 | 305 | 230 | 190 | 24 | 8-23 | 350 | 350 | 190 | 24 | 8-23 | |

125 | 356 | 245 | 210 | 22 | 8-18 | 356 | 270 | 220 | 28 | 8-25 | 400 | 270 | 220 | 28 | 8-25 | |

150 | 394 | 280 | 240 | 24 | 8-23 | 394 | 300 | 250 | 30 | 8-25 | 480 | 300 | 250 | 30 | 8-25 | |

200 | 457 | 335 | 295 | 28 | 12-23 | 457 | 360 | 310 | 34 | 12-25 | 600 | 375 | 320 | 38 | 12-30 | |

Tel: 15351513006

Landline: 0515-89118577

Fax: 0515-8911 8000

Email: jtongcn 126.com

Address: Oubei Pump and Valve Industrial Park, Binhai Economic Development Zone, Jiangsu Province

15351513006