D71J clamp type rubber lined butterfly valve/D671J pneumatic rubber lined butterfly valve/D971J electric rubber lined butterfly valve has a compact structure,easy 90°rotary switch,reliable sealing,and long service life.It is widely used in water plants,power plants,steel mills,papermaking,chemical,catering and other systems for water supply and discharge,as well as for regulating and shut-off purposes.

Characteristics of clamp type rubber lined butterfly valve products

1.This valve adopts a double eccentric structure,which has a sealing function that becomes tighter as it is closed,and the sealing performance is reliable.

2.The sealing auxiliary material is paired with stainless steel and nitrile oil resistant rubber,which has a long service life.

3.The rubber sealing ring can be located on the valve body or on the butterfly plate,and can be suitable for different characteristics of media for users to choose from.

4.The butterfly plate adopts a frame structure,with high strength,large overcurrent area,and low flow resistance.

5.The overall baking paint can effectively prevent rust and can be used in different media as long as the sealing material of the valve seat is replaced.

6.This valve has a bidirectional sealing function and is not controlled by the flow direction of the medium or the spatial position during installation.It can be installed in any direction.

7.The rubber lined butterfly valve has a unique structure,flexible operation,labor-saving,and convenience.

Scope of application of sealing materials for clamp type rubber lined butterfly valves

Material code for sealing ring | Temperature | Applicable Medium |

NR | ≤85℃ | Water, air, acid-base substances |

CR | ≤85℃ | Water, gas, acid-base substances |

NBR | ≤100℃ | Water and oil products |

EPDM | ≤120℃ | Water, steam, general acid-base substances |

FKM | ≤150℃ | Water, steam, strong acid-base substances |

Main component materials of clamp type rubber lined butterfly valve

Valve body | Cast iron, ductile iron, carbon steel, stainless steel |

Disc | Cast iron, ductile iron, carbon steel, stainless steel, carbon steel completely coated with rubber or fluoroplastic |

valve stem | Carbon steel nickel phosphorus plating, stainless steel |

Valve seat sealing ring | Natural rubber NR, chloroprene rubber CR, nitrile rubber NBR, EPDM, fluororubber FKM |

Worm gear device | Assembly |

test

Lining layer: Electric spark detection

Testing and inspection shall be conducted in accordance with GB/T13927 standard

Nominal pressure: PN (MPa)

Valve body: PN × 1.5

Sealing: PN × 1.1

Basic model of clamp type rubber lined butterfly valve

hand movement | D71J D71J Half lined | Worm gear transmission | D371J Half lined |

D71J fully lined | D371J fully lined | ||

D71F4 fully lined | D371F4 fully lined | ||

D71F46 fully lined | D371F46 fully lined | ||

pneumatic | D671JD71J Half lined | electric | D971J Half lined |

D671Jfully lined | D971J fully lined | ||

D671F4 fully lined | D971F4 fully lined | ||

D671F46 fully lined | D971F46 fully lined |

Design standard for clamp type rubber lined butterfly valve

Design and Manufacturing: GB12238

Structural length: GB12238

Flange connection size: GB4216

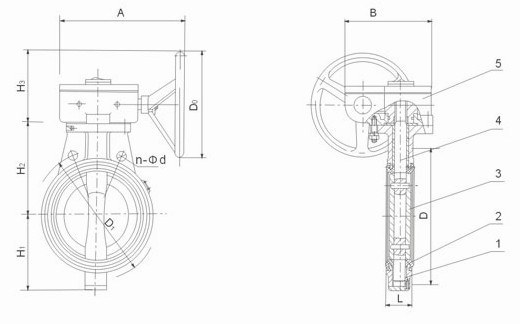

Parts list: 1. Valve body 2. Valve seat 3. Butterfly plate 4. Valve stem 5. Worm gear device

Main external dimensions of clamp type rubber lined butterfly valve

Nominal Diameter DN | nominal pressure MPa | Working pressure MPa | L | D | D1 | n-Φd | H1 | H2 | Do | H3 | A | B | quality |

40 | 1.0 | 1.0 | 33 | 150 | 110 | 4-18 | 55 | 100 | 150 | 62 | 164 | 125 | 6 |

50 | 43 | 165 | 125 | 4-18 | 64 | 120 | 150 | 62 | 164 | 125 | 7 | ||

65 | 46 | 185 | 145 | 4-18 | 80 | 120 | 208 | 62 | 164 | 125 | 10 | ||

80 | 46 | 200 | 160 | 8-18 | 112 | 130 | 260 | 62 | 164 | 125 | 11 | ||

100 | 52 | 220 | 180 | 8-18 | 90 | 140 | 275 | 62 | 164 | 125 | 12 | ||

125 | 56 | 250 | 210 | 8-18 | 112 | 160 | 350 | 106 | 289 | 200 | 18 | ||

150 | 56 | 285 | 240 | 8-22 | 135 | 175 | 350 | 106 | 289 | 200 | 29 | ||

200 | 60 | 340 | 295 | 8-22 | 160 | 210 | 240 | 106 | 289 | 200 | 34.5 | ||

250 | 0.6 | 68 | 395 | 350 | 12-22 | 206 | 235 | 240 | 106 | 289 | 200 | 44 | |

300 | 78 | 445 | 400 | 12-22 | 232 | 273 | 320 | 112 | 370 | 253 | 64.5 | ||

350 | 78 | 505 | 450 | 16-22 | 263 | 310 | 320 | 112 | 370 | 253 | 75.5 | ||

400 | 102 | 565 | 515 | 16-26 | 295 | 340 | 400 | 270 | 562 | 280 | 156 | ||

450 | 114 | 615 | 565 | 20-26 | 327 | 370 | 400 | 270 | 562 | 280 | 171.5 | ||

500 | 127 | 670 | 620 | 20-26 | 358 | 399 | 400 | 270 | 562 | 280 | 206.5 | ||

550 | 0.4 | 140 | 730 | 675 | 20-30 | 384 | 430 | 400 | 270 | 562 | 280 | 215 | |

600 | 154 | 780 | 725 | 20-30 | 474 | 460 | 500 | 270 | 562 | 280 | 283 | ||

700 | 165 | 895 | 840 | 24-30 | 486 | 510 | 500 | 125 | 503 | 443 | 426 | ||

800 | 190 | 1015 | 950 | 24-33 | 591 | 672 | 500 | 200 | 513 | 531 | 550 | ||

900 | 203 | 1115 | 1050 | 28-33 | 500 | 200 | 513 | 531 | 1070 | ||||

1000 | 216 | 1230 | 1160 | 28-36 | 721 | 800 | 550 | 273 | 713 | 815 | 1296 | ||

Tel: 15351513006

Landline: 0515-89118577

Fax: 0515-8911 8000

Email: jtongcn 126.com

Address: Oubei Pump and Valve Industrial Park, Binhai Economic Development Zone, Jiangsu Province

15351513006