The D943H electric flange hard seal butterfly valve adopts a precision J-shaped elastic sealing ring and a three eccentric multi-level metal hard seal structure. It is widely used in industrial pipelines such as metallurgy, power, petrochemicals, water supply and drainage, and municipal construction where the medium temperature is ≤ 425 ℃, for regulating flow and carrying fluids. The valve adopts a three eccentric structure, and the valve seat and disc sealing surface are made of different hardness and stainless steel, which has good corrosion resistance and long service life. This valve has bidirectional sealing function, and the product meets the national GB/T13927-92 valve pressure test standard.

characteristic

1. This valve adopts a three eccentric sealing structure, with almost no wear on the valve seat and butterfly plate, and has a sealing function that becomes tighter as viewed.

2. The sealing ring is made of stainless steel, which has the dual advantages of metal hard sealing and elastic sealing. It has excellent sealing performance in both low and high temperatures, corrosion resistance, and long service life.

3. The sealing surface of the disc plate is made of cobalt based hard alloy by welding, which is wear-resistant and has a long service life

4. The large-sized butterfly plate adopts a frame structure with high strength, large overcurrent area, and low flow resistance.

5. This valve has a bidirectional sealing function, which is not limited by the flow direction of the medium or the spatial position during installation, and can be installed in any direction.

6. The driving device can be installed in multiple stations (rotated 90 ° or 180 °) for easy user use.

Technical parameters of electric flange hard seal butterfly valve

The nominal TongjingDN(mm) | 50~2000 | |||

Nominal pharmacologyPN(MPa) | 0.6 | 1.0 | 1.6 | 2.5 |

Sealing test(MPa) | 0.66 | 1.1 | 1.76 | 2.75 |

Strength test(MPa) | 0.9 | 1.5 | 2.4 | 3.75 |

Temperature | carbon steel:-29℃~425℃ stainless steel:-40℃~650℃ | |||

Applicable Medium | Water, air, natural gas, oil products, and weakly corrosive fluids | |||

leakage | Compliant with GB/T13927-92 standard | |||

Drive mode | Worm gear transmission, electric, pneumatic, hydraulic | |||

Electric flange hard seal butterfly valve parts material

Part name | 材料 |

valve body | WCB、 Alloy steel, stainless steel, QT450-10 |

Disc | WCB、 Alloy steel, stainless steel, QT450-10 |

valve shaft | 2Cr13 stainless steel, alloy steel |

sealing ring | Stainless steel ring |

filler | Flexible graphite |

Electric flange hard seal butterfly valve execution standard

manufacturer's standard | JB/T 8527-97 |

Flange standard | GB9113-2000 |

Structural length standard | GB12221-89 |

Inspection standards | GB/T 13927-92 |

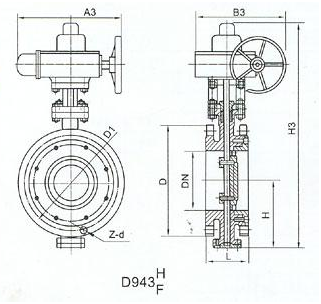

Dimensions of electric flange hard seal butterfly valve

Nominal Diameter (DN) | Dimensions | Flange size and bolt specifications | ||||||||||

1.0MPa | 1.6MPa | 2.5MPa | ||||||||||

L | H1 | H | D | D1 | n-Фd | D | D1 | n-Фd | D | D1 | n-Фd | |

50 | 108 | 530 | 112 | 165 | 125 | 4-18 | 165 | 125 | 4-18 | 165 | 125 | 4-18 |

65 | 112 | 530 | 115 | 185 | 145 | 4-18 | 185 | 145 | 4-18 | 185 | 145 | 8-18 |

80 | 114 | 565 | 120 | 200 | 160 | 4-18 | 200 | 160 | 8-18 | 200 | 160 | 8-18 |

100 | 127 | 600 | 138 | 220 | 180 | 8-18 | 220 | 180 | 8-18 | 235 | 190 | 8-22 |

125 | 140 | 640 | 164 | 250 | 210 | 8-18 | 250 | 210 | 8-18 | 270 | 220 | 8-26 |

150 | 140 | 705 | 175 | 285 | 240 | 8-22 | 285 | 240 | 8-22 | 300 | 250 | 8-26 |

200 | 152 | 775 | 200 | 340 | 295 | 8-22 | 340 | 295 | 12-22 | 360 | 310 | 12-26 |

250 | 165 | 945 | 243 | 395 | 350 | 12-22 | 405 | 355 | 12-26 | 425 | 370 | 12-30 |

300 | 178 | 1070 | 250 | 445 | 400 | 12-22 | 460 | 410 | 12-26 | 485 | 430 | 16-30 |

350 | 190 | 1140 | 280 | 505 | 460 | 16-22 | 520 | 470 | 12-26 | 555 | 490 | 16-33 |

400 | 216 | 1210 | 305 | 565 | 515 | 16-26 | 580 | 525 | 16-26 | 620 | 550 | 16-36 |

450 | 222 | 1335 | 350 | 615 | 565 | 20-26 | 640 | 585 | 16-30 | 670 | 600 | 20-36 |

500 | 229 | 1415 | 380 | 670 | 620 | 20-26 | 715 | 650 | 20-30 | 730 | 660 | 20-36 |

600 | 267 | 1605 | 445 | 780 | 725 | 20-30 | 840 | 770 | 20-33 | 845 | 770 | 20-39 |

700 | 292 | 1844 | 480 | 895 | 840 | 24-30 | 910 | 840 | 24-36 | 960 | 875 | 24-42 |

800 | 318 | 2040 | 530 | 1015 | 950 | 24-33 | 1025 | 950 | 24-39 | 1085 | 990 | 24-48 |

900 | 330 | 2255 | 580 | 1115 | 1050 | 28-33 | 1125 | 1050 | 28-39 | 1185 | 1090 | 28-48 |

1000 | 410 | 2380 | 650 | 1230 | 1160 | 28-36 | 1255 | 1170 | 28-42 | 1320 | 1210 | 28-56 |

1200 | 470 | 2640 | 760 | 1455 | 1380 | 32-39 | 1485 | 1390 | 32-48 | 1530 | 1420 | 32-56 |

1400 | 530 | 2886 | 850 | 1675 | 1590 | 36-42 | 1685 | 1590 | 36-48 | 1755 | 1640 | 36-62 |

1600 | 600 | 3156 | 1030 | 1915 | 1820 | 40-48 | 1930 | 1820 | 40-56 | 1975 | 1860 | 40-62 |

1800 | 670 | 3421 | 1230 | 2115 | 2020 | 44-48 | 2130 | 2020 | 44-56 | 2195 | 2070 | 44-70 |

2000 | 760 | 3685 | 1350 | 2325 | 2230 | 48-48 | 2345 | 2230 | 48-62 | 2425 | 2300 | 48-70 |

Tel: 15351513006

Landline: 0515-89118577

Fax: 0515-8911 8000

Email: jtongcn 126.com

Address: Oubei Pump and Valve Industrial Park, Binhai Economic Development Zone, Jiangsu Province

15351513006