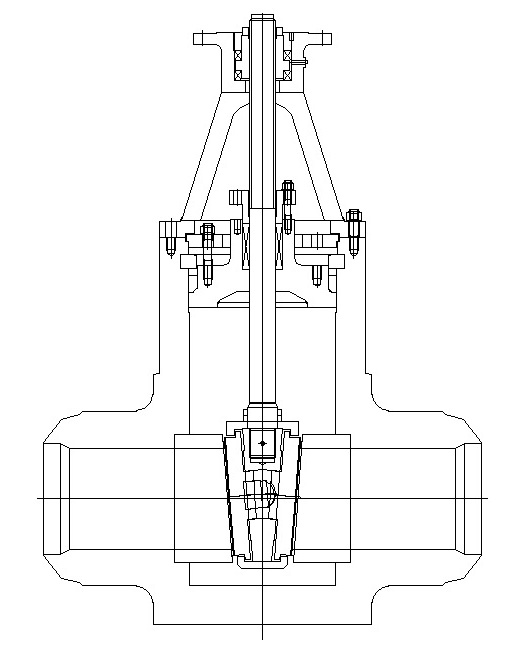

Self sealing forged gate valve

1、Usage and Performance Specifications

High temperature and high pressure power station gate valves,also known as power station specific valves,are mainly suitable for cutting off or connecting pipeline media in various systems of thermal power stations.Applicable media:non corrosive media such as water and steam.

The characteristics of power station valves compared to other valve products are high temperature and high pressure,unique self sealing design,and the higher the pressure,the more reliable the seal.Due to its unique performance,technical characteristics,and working conditions,the product has also developed unique features that cannot be replaced by other products.

The opening and closing component of a gate valve is the gate plate,and the direction of movement of the gate plate is perpendicular to the direction of the fluid.The gate valve can only be fully opened and fully closed,and cannot be adjusted or throttled.The gate valve has two sealing surfaces.The two sealing surfaces of the commonly used mode gate valve form a wedge shape,and the wedge angle varies with the valve parameters.The gate of the wedge gate valve can be made as a whole,called a rigid gate valve;It can also be made into a gate that can produce slight deformation to improve its processability and compensate for the deviation of the sealing surface angle during the processing.This type of gate is called an elastic gate.When the gate valve is closed,the sealing surface can be sealed solely by the medium pressure,that is,the sealing surface of the gate is pressed against the valve seat on the other side by the medium pressure to ensure the sealing of the sealing surface.Most gate valves use forced sealing,which means that when the valve is closed,external force must be used to forcefully press the gate plate against the valve seat to ensure the sealing performance of the sealing surface.

2、Advantages

1.The use of a straight through structure with equal diameter channels greatly reduces the flow resistance coefficient and energy loss,significantly improving the service life and performance of the valve.

2.The valve chamber adopts a pressure self tightening sealing structure with good sealing performance.

3.The sealing surface of the gate and valve seat is made of hard alloy welding,which has good wear resistance,high temperature resistance,corrosion resistance,and abrasion resistance.

4.The surface of the valve stem is treated with corrosion-resistant nitriding,which has good corrosion resistance and scratch resistance.

5.The structure of the opening and closing components can be designed in different forms such as single board,double board,parallel double board,etc.according to user requirements.

3、Design specifications

1.Design standards

Design and Manufacturing GB/T12234 ASMEB16.34

Structural length JB/T3595 GB/T15188 GB/T12221

Interface connection dimensions JB/T3595 GB/T12224

Inspection and Testing JB/T3595 MSS SP61

Pressure and Temperature Reference JB/T3595 ANSI B16.34

2.Main pressure levels of gate valves for high temperature and high pressure power stations

Nominal pressure 200,250,320

Work pressure P 54 100V P 54 140V、P 54 170V

3.Standards related to gate valves for high temperature and high pressure power plants

JBT 3595-2002 General Requirements for Power Station Valves

JB/T 5263-2005 Technical Conditions for Steel Castings of Power Station Valves

JB/T 4018 Method for Model Designation of Power Station Valves

DL 959-2005 Guidelines for the Application of Safety Valves in Power Plant Boilers

DLT 531-1994 Technical Conditions for High Temperature and High Pressure Stop Valve and Gate Valve of Power Station

DLT 641-2005 Electric actuator for power station valves

DLT 850-2004 Power Station Piping

GB 10869 Technical Conditions for Power Station Regulating Valves

GBT 10868-2005 Power Station Temperature and Pressure Reducing Valve

4、Component materials

Valve body:WCB ZG20CrMoV A105 WC6 WC9

Internal components:20#12Cr1MoV

5、Installation

This series of valves should be installed vertically or horizontally.

6、Maintenance,upkeep,and usage precautions

1.Valves should be stored in a dry and ventilated room,and both ends of the valve should be blocked.

2.Valves stored for a long time should be regularly inspected and cleaned of dirt.Special attention should be paid to the cleanliness of the sealing surface to prevent damage.

3.Before installation,carefully check whether the valve markings match the usage requirements.

4.Before installation,the valve cavity and sealing surface should be checked.If there is dirt,it should be wiped clean with a cleaning cloth.

5.Valves should be regularly inspected after use,checking the sealing surface of the main pipeline and the sealing surface of the bypass.If damaged or ineffective,it should be repaired or replaced in a timely manner.

7、Main appearance

Tel: 15351513006

Landline: 0515-89118577

Fax: 0515-8911 8000

Email: jtongcn 126.com

Address: Oubei Pump and Valve Industrial Park, Binhai Economic Development Zone, Jiangsu Province

15351513006