Welded globe valves are suitable for cutting off or connecting media in pipelines of various working conditions such as petroleum,chemical,hydraulic,and thermal power plants with nominal pressures ranging from PN10.0 to 32.0Mpa and P(54)100V to P(57)170V,and working temperatures≤540℃(where P(57)170V has a working temperature of 570℃).Applicable media include water,oil,steam,etc.The operation modes include manual,gear transmission,electric,etc.

Structural characteristics of welded globe valve

1.The product design and manufacturing shall comply with the provisions of E101 and JB/T3595-93 standards,with a reasonable structure,excellent performance,and beautiful appearance.

2.The valve chamber adopts a pressure self tightening sealing structure,and the better the sealing performance.The two ends of the branch pipe are welded structures.Welding grooves can be matched according to standards or user requirements.

3.The sealing surfaces of the valve disc and seat are made of Stellite cobalt based hard alloy,which is wear-resistant,high-temperature resistant,has good abrasion resistance,and has a long service life.

4.The valve stem has undergone quenching and surface nitriding treatment,which provides good corrosion resistance and abrasion resistance.

5.The depth of the valve cover packing box is reasonable,and corrosion inhibitors are added to the packing to ensure reliable sealing.

6.The electric globe valve is equipped with a DZW series valve electric device,which has the characteristics of small housing,light weight,comprehensive functions,and beautiful appearance.It can also be used in conjunction with a programmable computer or an electric device can be selected according to user requirements.

Standard specification for welding globe valves

Design and Manufacturing:E101,JB/T3595-93

Pressure and temperature:E101,JB/T3595

Structural length:E101

Welding connection size:GB/T15198.3-95

Inspection and Experimentation:GB/T13927-92

Main performance parameters of welding globe valve

Model | nominal pressure | test pressure | Working pressure | operation temperature(℃) | Applicable Medium | |||

Shell strength | seal | P54 | P55 | P57 | ||||

J61H/Y-100 | 10 | 15 | 11 | ≤450 | Water, steam, oil products | |||

J61H/Y-200 | 20 | 30 | 22 | |||||

J61H/Y-250 | 25 | 38 | 28 | |||||

J61H/Y-320 | 32 | 48 | 36 | |||||

J61Y-P54/100V | 30 | 22 | 10 | ≤540 | steam | |||

J61Y-P54/140V | 38 | 28 | 14 | |||||

J61Y-P54/170V | 48 | 36 | 17 | 10 | ||||

J61Y-P55/100V | 38 | 28 | 14 | ≤555 | ||||

J61Y-P55/140V | 48 | 36 | 17 | |||||

J61Y-P55/170V | 53 | 39 | 10 | |||||

J61Y-P57/100V | 48 | 36 | 14 | ≤570 | ||||

J61Y-P57/140V | 55 | 40 | 17 | |||||

J61Y-P57/170V | 60 | 44 | ||||||

Main component materials of welding globe valve

Part name | valve body | bonnet | valve stem | Valve flap | Sealing surface | filler | stem nut | handwheel | fastener |

J61H type | 25 | 25 | Chromium stainless steel | chromium stainless steel | chromium stainless steel | Flexible graphite | Aluminum bronze | malleable iron | High quality carbon steel molybdenum steel |

J61Y type | 25 | 25 | Chromium stainless steel | 25 | hard metal | Flexible graphite | Aluminum bronze | malleable iron | High quality carbon steel chromium molybdenum steel |

J61Y-P54 type | ZG20CrMolV 12CrlMolV | 12C r1MolV | 20CrMol V | 12CrlMolV | hard metal | Flexible graphite | Aluminum bronze | malleable iron | chromium molybdenum steel |

J61Y-P55 type | ZG25CrMol V12CrlMolV | 12C r1MolV | 20CrMol V | 12C r1MolV | hard metal | Flexible graphite | Aluminum bronze | malleable iron | chromium molybdenum steel |

J61Y-P57 type | ZGl5CrMolV 12CrlMolV | 12CrlMolV | 20CrMol V25CrlMolV | 12CrlMolV | hard metal | Flexible graphite | Aluminum bronze | malleable iron | chromium molybdenum steel |

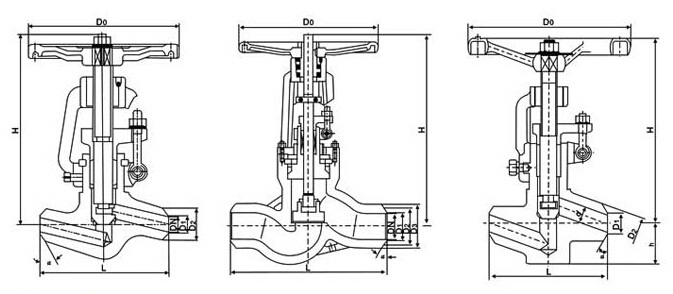

Main external dimensions of welded globe valve

Nominal DiameterDN | Main external dimensions and connection dimensions(mm) | weight(kg) | ||||||

L | D1 | D2 | D3 | α | H | D0 | ||

J61(H.Y)-25、40、64、100、200、250、320 J61Y-P54/100V、P54/140V、P54/170V | ||||||||

10 | 120 | 12 | 25 | 40° | 185 | 140 | 2.8 | |

15 | 170 | 17 | 36 | 40° | 247 | 200 | 7.5 | |

20 | 170 | 22 | 42 | 40° | 248 | 200 | 9 | |

25 | 170 | 26 | 42 | 40° | 248 | 240 | 9.5 | |

32 | 170 | 31 | 44 | 40° | 248.5 | 280 | 15 | |

50① | 250 | 50 | 82 | 32° | 450 | 320 | 60 | |

50② | 350 | 50 | 82 | 32° | 450 | 320 | 64 | |

65 | 430 | 69 | 100 | 110 | 32° | 669 | 400 | 74 |

80 | 470 | 84 | 108 | 130 | 32° | 669 | 450 | 112.5 |

100 | 560 | 107 | 144 | 165 | 32° | 755 | 500 | 178.5 |

Note: DN50 comes in two models. | ||||||||

J61Y-P55/100V、P55/140V、P55/170V J61Y-P57/100V、P57/140V、P57/170V | ||||||||

10 | 120 | 12 | 28 | 40° | 189 | 140 | 3 | |

15 | 170 | 17 | 40 | 40° | 250 | 200 | 9 | |

20 | 170 | 22 | 46 | 40° | 252 | 200 | 11 | |

25 | 170 | 26 | 46 | 40° | 254 | 240 | 13 | |

32 | 170 | 31 | 49 | 40° | 254 | 280 | 17 | |

50① | 250 | 50 | 90 | 32° | 453 | 320 | 68 | |

50② | 350 | 50 | 90 | 32° | 455 | 320 | 72 | |

65 | 430 | 69 | 104 | 115 | 32° | 630 | 400 | 83 |

80 | 470 | 84 | 110 | 140 | 32° | 672 | 450 | 118 |

100 | 560 | 17 | 148 | 170 | 32° | 761 | 500 | 165 |

Tel: 15351513006

Landline: 0515-89118577

Fax: 0515-8911 8000

Email: jtongcn 126.com

Address: Oubei Pump and Valve Industrial Park, Binhai Economic Development Zone, Jiangsu Province

15351513006